News

Selecting appropriate vacuum lifting equipment requires careful consideration of cargo dimensions, material characteristics, and total weight.

A scrap grab crane acts like a human hand, designed to grip and move a wide variety of bulk materials. It’s commonly used for handling waste, logs, minerals, coal, sand, and earth.

The hook is an indispensable component for a double-girder crane and is also a key component for the normal use of the crane.

Many companies, when starting out or expanding their operations, often encounter the question of whether to choose new cranes or used cranes when it comes to the procurement of lifting equipment.

As essential heavy-duty equipment, cranes frequently handle demanding loads, making their components prone to wear over time.

Wheel set refers to the mechanical equipment composed of wheels and shafts, bearings and bearing boxes, etc., which is used to support the crane and the load, and make the crane reciprocating on the track.

Crane wheels primarily serve heavy-duty applications in metallurgical enterprises, including:

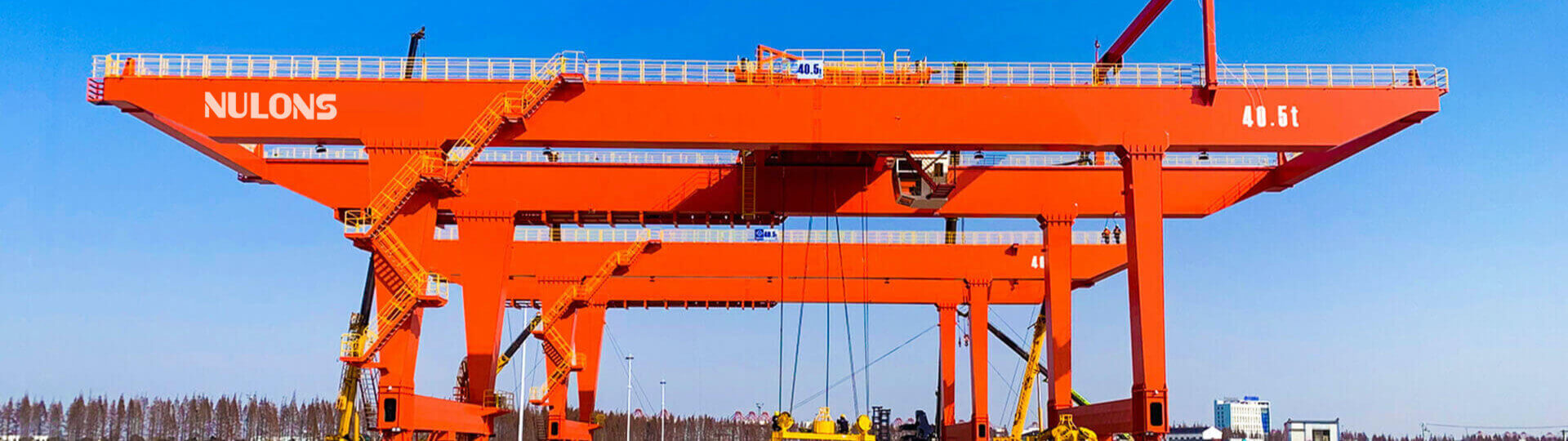

A gantry crane, also known as a gantry crane, is a variation of the bridge crane. It’s primarily used for loading and unloading bulk cargo in outdoor cargo yards, material storage areas, and warehouses.

We design cranes that meet your needs. Whether you need to increase safety, maximize production capacity or reliability, or reduce costs, we deliver.