Description

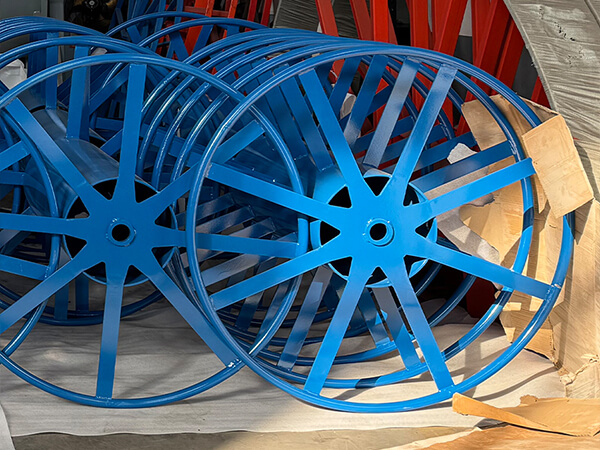

Cable reels are specialized reels for wires and cables. They are typically constructed of steel or steel-wood. Steel reels are sturdy, durable, provide good cable protection, and are reusable.

Working Condition

The operating conditions of winding reels mainly involve environmental factors (temperature, humidity, wind, dust), mechanical load (wire tension, speed, reel weight), electrical performance (wire specifications, insulation requirements), and safety regulations (grounding, protection). Different types of winding reels (such as high-speed, industrial, and portable) have specific requirements, which must be considered comprehensively to ensure safety and efficiency.

1. Environmental Factors

Temperature and Humidity: Must adapt to the production environment to avoid extreme temperatures and high humidity that could degrade the wire/reel material.

Wind: When used outdoors or in ventilated areas, the impact of wind must be considered, especially for high-speed reels, to prevent wire vibration or tangling.

Dust and Corrosion: Dust and corrosive media in the production environment can affect the reel and wire, requiring appropriate protection or materials.

2. Mechanical & Operational Conditions

Linear Speed and Tension: High-speed reels must be able to withstand high linear speeds (e.g., >50m/s) and the tension of the wire.

**Spool Load Capacity:** The spool’s structure and material (wood, steel, plastic) must be able to support the weight and turnover requirements of the wound wire.

**Stable Operation:** Ensure smooth spool operation, reduce vibration, and prevent wire jumping or slippage.

**Compatibility:** The spool’s interface and speed must match the supporting equipment (wire drawing machine, take-up and unwinding machine).

3. Electrical and Wire Requirements

**Wire Specifications:** Consider wire diameter, material (copper/aluminum), and insulation thickness to ensure compatibility with the spool.

**Insulation Performance:** Good insulation is required at the wire and spool connections to prevent short circuits and electric shock.

**Grounding Requirements:** Grounding is mandatory in electrical operations to ensure safety.

Features

This wire reel can be manufactured according to customer requirements or in accordance with standards such as GB4004-83, JB/T8997.4-2013, and DIN46397.

This wire reel is made of stamped steel plate, ensuring high concentricity, good rigidity, durability, and resistance to deformation.

This wire reel can be customized according to customer requirements.

The wire reel can be used for cables, wires, cords, flat wires, hoses, etc.: stainless steel wire, high carbon steel wire, medium carbon steel wire, low carbon steel wire, welding wire, steel cord, steel wire rope, copper and aluminum single bundles, insulated and sheathed wires and cables.

The wire reel can be used in all wire drawing machines, such as wire drawing and rope making.

The wire reel can be used for winding or unwinding in cage stranding machines, tube stranding machines, bow stranding machines, wire bundling machines, and cable forming machines.

The wire reel can also be used as a disposable delivery reel.

Technical Data

| Cable specifications and outer diameter (mm) / cable length (m) / reel weight (kg) / reel size (mm) | H | Inner diameter D | 1800 | 2200 | 2600 | 3000 | 3400 | 3800 | 4200 |

| CFR(14*1.5).∅25.9 | 32 | 900 | 75/184 | 128/224 | 191/264 | 265/304 | |||

| CFR(24*1.5),∅32.6 | 40 | 58/190 | 100/230 | 150/270 | 208/310 | 276/350 | |||

| YCW(3*70+1*25).∅51 | 64 | 1200 | 60/300 | 87/340 | 118/380 | 153/420 | 193/460 | ||

| YGF(3*35+1*16),∅52 | |||||||||

| YCM(3*120+1*35),∅60 | 74 | 51/310 | 74/350 | 101/390 | 132/430 | 165/470 | |||

| GBF(3*35+1*16),40*60 | 80/310 | 115/350 | 156/390 | 202/430 | 254/470 | ||||

Service

1. Providing standardized and specification-compliant products.

2. Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.